Fiberglass Pultrusion Profiles For the Construction Industry

An increasing number of architects, engineers and builders are using fiberglass pultrusion for a variety of building and infrastructure projects and the trend is accelerating thanks to the many benefits delivered by the technology.

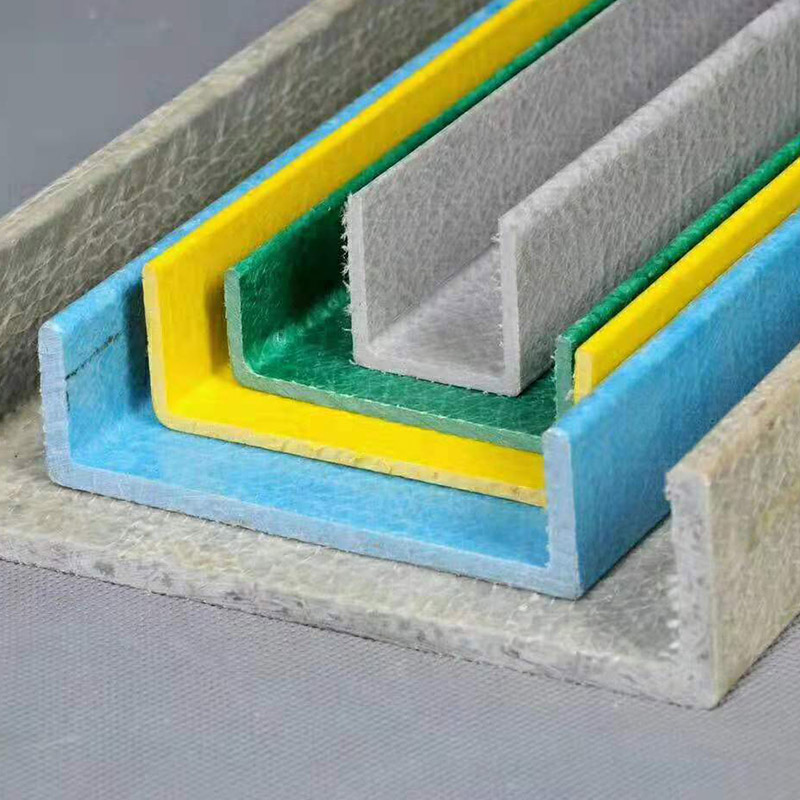

Pultrusion is a process for producing linear fiber-reinforced plastic (FRP) composite profiles with a uniform cross-section. The pultrusion machine reinforces the fiber by impregnating them in a resin bath and then pulls it through a heated die in which the curing occurs.

The finished profiles can be of virtually any cross-sectional shape (e.g., tubes, rods, I-beams, T-, U- and Z-profiles) that are either solid or hollow, then be cut to the desired length.

The manufacturing process is highly automated, making pultrusion a fast and efficient method for producing high-performance building parts of various shapes and sizes that allow for much design freedom.

Benefits Of Using Pultruded Fiberglass In Building and Construction

Pultrusion offers a flexible and scalable solution for creating items such as profiles or reinforcements for windows, doors, and frames, pipe and electrical supports, as well as roll-up door panels.

Here are some key advantages of using pultruded fiberglass profiles in construction:

The pultrusion process allows for rapid, cost-effective, and high-volume manufacturing of structural components that are strong, durable, and lightweight. In addition, you can accurately-control the resin content to adjust the properties and load-bearing capacity of the end products.

Components of various characteristics can be created by using a range of reinforcing fibers and formats, such as glass or carbon fiber and thermoset matrix resins (e.g., polyester, vinylester, epoxy, phenolic, polyurethane, and thermoplastic resins.)

Pigments can be added during the pultrusion process to create fiberglass profiles of any color, eliminating the time and cost required for painting. Surfacing veils can also be used to create appearances such as wood grain, marble, and granite to meet different design needs.

The corrosion-resistant properties of composite materials provide a durable and low maintenance solution for products that are exposed to the weather. For example, pultruded roof trim, fascia, and soffit are lightweight and easy to install.

A durable UV-resistant coating can be applied to pultruded fiberglass profiles for outdoor use to increase the durability of the components cost-effectively.

Additional resources:What is HDPE pipe prices?

What are the advantages of uPVC pipe?

Which supplier offers the best nylon sheets for sale?

Which Innovative Projects Can Utilize 6mm Plastic Sheets?

How do you keep rubber mats from slipping?

Vintage T-Shape Bakelite Knobs: Timeless Elegance

Which HDPE pipe prices in Kenya offer the best value for money?

Fiberglass profiles are easy to manipulate without the need for specialized tools. For example, they can be painted, cut or drilled using conventional hardened tools, and connected using bolts, screws, rivets, or adhesives at the construction sites.

The pultrusion process offers virtually endless options for customization to meet various structural and design requirements.

FRP Pultruded profiles can be as much as 75% lighter than their steel counterparts without sacrificing structural strength.

Fiberglass profiles are effective thermal breaks that prevent thermal bridging, which is a common challenge for steel and concrete and impacts a building's energy performance. Pultruded composites can effectively reduce heat conduction and therefore energy consumption of a building while preventing the formation of surface condensation.

Transportation of the lightweight pultruded components is easy and inexpensive, which helps lower the overall cost of a building project.

Glass fiber reinforced plastic (GRP) rebars can maintain their micro-structural integrity and mechanical properties for more than 15 years with very low maintenance requirements. The high durability enhances long-term performance while lowering the lifecycle cost of the building structures.

Pultruded composites are extremely durable, have a long service life, require little maintenance, and mostly recyclable -- making them popular among architects, designers, developers, and builders since sustainability is now a key criterion for many construction projects.

Conclusion

With the many advantages, no wonder pultruded fiberglass profiles are widely adopted by designers, builders, and homeowners in a variety of applications, such as energy-efficient windows and doors, thermal breaks, window reinforcements, exterior trim, cladding, pergolas and arbors, columns, fencing and decking systems, and affordable modular housing systems.

The materials are well-recognized for their superior performance in dimensional stability and thermal performance -- making them a great alternative for wood, PVC, steel, and aluminum in a variety of applications to achieve high cost-efficiency.

Pultruded composites' low maintenance requirements, durability, and high strength characteristics also help homeowners reduce maintenance expenses and enable contractors to minimize recalls.

What to Know About the Toxicity of Polypropylene

What is the purpose of rubber grommets?

Which HDPE pipe floats provide the best value for money?

Which factors to consider when purchasing UHMW-PE fender panels and sills?

What are the disadvantages of Viton?

What are the advantages of purchasing Longya Rubber?

Ultimate Guide: Choosing and Using Rubber O-Rings

274

0

0

Related Articles

-

Which Industries Can Benefit from High Abrasion Resistance Nr Rubber Sheets?

Which Industries Can Benefit from High Abrasion Resistance NR Rubber Sheets?

34

0

0

-

26

0

0

-

34

0

0

-

32

0

0

-

36

0

0

-

32

0

0

-

Revolutionizing Mining Operations: Why PE Pipes?

In the world of mining operations, efficiency, reliability, and safety are paramount.

32

0

0

-

20

0

0

Comments

All Comments (0)