Types of hydraulic cylinder oil seals

Mar. 27, 2024

Hydraulic cylinder oil seals are essential components in hydraulic systems, serving to prevent fluid leakage and maintain system efficiency. These seals are subjected to high pressure, temperature, and friction, making their design and material selection crucial for optimal performance.

Rod Seals: Rod seals, also known as shaft seals or piston seals, are installed on the rod or shaft of the hydraulic cylinder to prevent leakage of hydraulic fluid from the cylinder to the external environment. They also help to retain lubrication on the cylinder rod, reducing friction and wear. Rod seals are typically made of materials such as polyurethane, rubber, or PTFE (polytetrafluoroethylene), chosen for their durability and resistance to hydraulic fluids.

Piston Seals: Piston seals are located inside the hydraulic cylinder, sealing the gap between the piston and the cylinder bore. They prevent fluid from bypassing the piston and ensure proper pressure buildup within the cylinder. Piston seals are often made of materials such as nitrile rubber, polyurethane, or PTFE, depending on the specific application requirements.

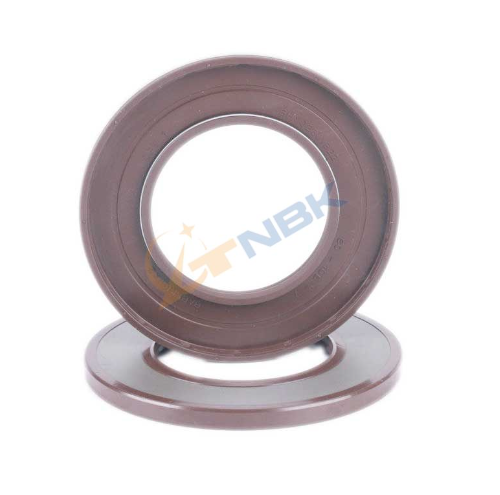

Wiper Seals: Wiper seals, also known as scraper seals or dust seals, are installed on the outer diameter of the hydraulic cylinder to prevent contaminants such as dust, dirt, and moisture from entering the system. They also help to remove debris from the rod surface as it retracts into the cylinder, preventing damage to the rod seals and extending their service life. Wiper seals are typically made of elastomeric materials such as nitrile rubber or polyurethane.

Wear Rings: Wear rings, also known as guide rings or bearing rings, are installed on the piston or cylinder bore to guide the piston and prevent metal-to-metal contact. They help to minimize friction, reduce wear, and improve the overall efficiency of the hydraulic system. Wear rings are commonly made of materials such as bronze, PTFE, or filled PTFE.

Buffer Seals: Buffer seals, also known as cushion seals or bumper seals, are used in hydraulic cylinders to provide cushioning and absorb shock during the piston's end-of-stroke impact with the cylinder head. They help to prevent damage to the cylinder components and reduce noise and vibration. Buffer seals are typically made of materials such as polyurethane or rubber.

Backup Rings: Backup rings, also known as support rings or anti-extrusion rings, are used in conjunction with rod seals and piston seals to provide additional support and prevent extrusion of the sealing element under high pressure. They help to extend the service life of the primary seals and maintain sealing integrity in demanding operating conditions. Backup rings are commonly made of materials such as PTFE, rubber, or thermoplastic.

Hydraulic cylinder oil seals play a critical role in maintaining the performance and reliability of hydraulic systems. By understanding the different types of oil seals available and their specific functions and applications, hydraulic system operators can select the most suitable seals for their requirements and ensure optimal system performance and longevity.

20

0

0

None

None

Comments

All Comments (0)