Interpretation of the key points of concrete saw blades in cutting bridges

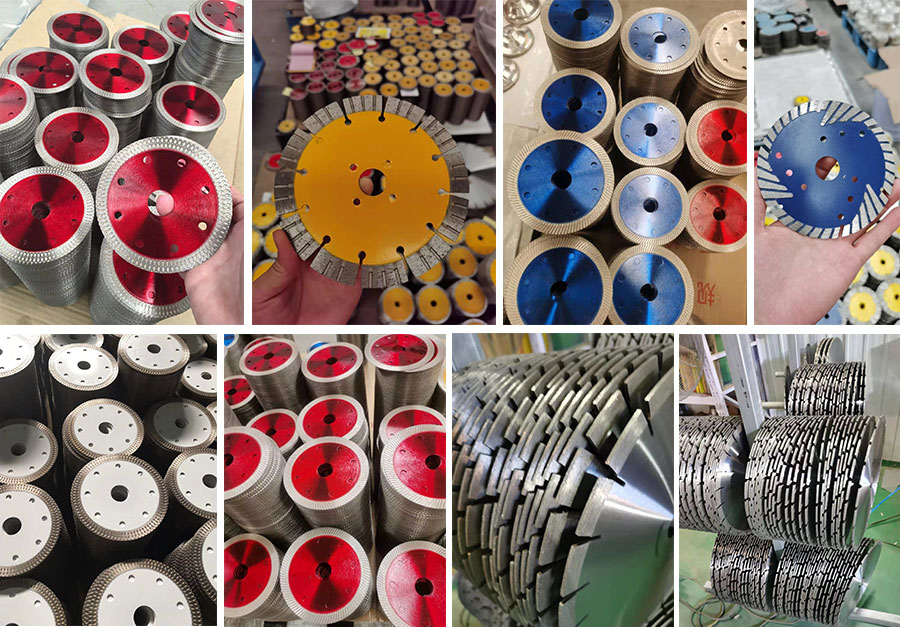

A concrete saw blade is a tool accessory used for cutting concrete and similar materials. It is commonly used in construction, road maintenance, bridge construction and other projects that require concrete cutting. Concrete saw blades come with some special designs and features to ensure that they can effectively cut through hard concrete materials while providing a long service life.

1. Concrete saw blade cutting bridge-construction preparation work

(1) During the construction of prefabricated beam slabs and abutment back walls, anchoring steel bars should be pre-embedded and notches reserved according to design requirements.

(2) When installing beams and plates, the size of the gaps should be appropriately adjusted on the piers and platforms where the bridge expansion joints are installed to meet the width required for installing the bridge expansion joint devices.

(3) In order to ensure the passage of construction vehicles before paving the asphalt pavement, fill the slots and between the embedded steel bars with sand or sandy soil. The top surface of the exposed part should be 1-2cm higher than the top surface of the embedded steel bars. To protect the steel bars from being crushed.

(4) Before the construction of bridge expansion joints, a detailed construction organization design plan is required to be submitted, which requires careful organization, overall arrangements, clear responsibilities, clear responsibilities, and strict control in accordance with construction specifications.

(5) Be familiar with the drawings, installation operating procedures, and conduct construction operating procedures training, check the position numbers of the bridge expansion joints, and inspect and accept the straightness, flatness, twist, and spacing of the bridge expansion joints.

2. Concrete saw blade cutting bridge--transportation of bridge expansion joint device

(1) Bridge expansion joint devices are usually in groups of four, which are already fixed when supplied by the manufacturer. The telescopic device should be bundled as a whole on the flatbed truck, and it should be driven slowly when turning to prevent overturning.

Additional resources:What does an air booster do?

What makes a tool non sparking?

Is a refrigerant pumping system a smart investment for businesses?

How does a gas booster work? All your questions answered!

Discover the Power of SK129 Speed Handle

Is Gas Helper the Best Purchase for B2B Marketing?

Discover the Safety Benefits of Non Sparking Beryllium Copper Hammer

(2) The telescopic devices should be transported to the bridge construction site according to each bridge classification and checked in detail.

3. Concrete saw blade cutting bridge--installation of bridge expansion joints

(1) Cutting seams

After the asphalt concrete paving and curing of the bridge deck is completed, the joints will be cut. Before starting the joint cutting, the flatness of the asphalt pavement must be tested. When the test results meet the requirements, the slot width will be determined according to the construction drawings and accurately measured and set out. Generally, two colored nylon ropes can be pulled as reference lines for cutting seams, which can ensure accurate size and smooth cutting seams.

(2) Grooving

Use a pneumatic pick to make grooves, and the depth of the concrete saw blade shall not be less than 12cm. First, use a pneumatic pick to remove the portion of the asphalt pavement between the two cuts. After the bridge expansion joints are slotted, all debris in the slots should be removed, and the remaining residue should be washed away with a high-pressure water gun. The concrete pavement of roads and bridges outside the cutting line must be covered with colored strips of cloth or steel plates for protection before opening the seams. This way, on the one hand, the debris generated by the slotting can be placed on it, and on the other hand, it can prevent the debris generated during the cutting. Stone dust pollutes the road surface.

Please note that concrete saw blades can vary depending on the depth of cut required, material type and working conditions. Before purchasing a concrete saw blade, it is recommended to consult a professional or supplier to ensure you select the blade that best suits your project needs. Additionally, be sure to follow safety guidelines when using a concrete saw blade to keep yourself and others safe.

How to Make Circular Saw Blades Last Longer?

Unleashing Power: The Ultimate Liquid Booster Pump

Everything You Need to Know About Non-Sparking Adjustable Combination Pliers

Is vacuum limiting valve testing worth the investment?

Top Non-Sparking Ratchet Wrench: European Type Guide

Top 5 Tips for Efficient Extinguisher Filling Process?

Which Non Sparking Ratchet Wrench with Retractable Handle offers the best value for money?

How do I choose the right circular saw blade for my project?

230

0

0

Related Articles

-

289

0

0

-

284

0

0

-

266

0

0

-

What are the applications of TCT tools?

In the world of cutting and shaping materials, precision, efficiency, and durability are paramount.

303

0

0

-

242

0

0

-

220

0

0

-

When was the pry bar invented?

Tools have played a vital role in human civilization, enabling us to build, repair, and create.

232

0

0

-

What is a cordless drill best used for?

Cordless drills have become an indispensable tool in the world of DIY and professional construction.

223

0

0

Comments

All Comments (0)