Which Custom Injection Molding Technique Reigns Supreme?

Which Custom Injection Molding Technique Reigns Supreme?

Custom injection molding is a widely utilized fabrication process in the manufacturing industry. It allows for the production of intricate and precise plastic components. However, with the myriad of techniques available, it can be challenging to determine which one is superior. After a thorough analysis of various factors, it becomes clear that the injection molding technique known as gas-assisted injection molding (GAIM) reigns supreme.

Firstly, GAIM allows for the production of parts with complex geometries and intricate designs. The gas channels created within the component enable the molding of undercuts, thick walls, and internal features that may not be possible with conventional injection molding techniques. This opens up a world of possibilities for designers and engineers, as they can now create products with increased functionality and aesthetics.

Secondly, the hollow structure achieved through GAIM reduces material consumption. By using less plastic, manufacturers can reduce production costs and address environmental concerns by minimizing waste. Additionally, the lightweight nature of GAIM-produced parts makes them ideal for industries where weight reduction is critical, such as automotive and aerospace. These lightweight components contribute to improved fuel efficiency, increased payload capacity, and enhanced performance.

Additional resources:How do you choose plastic material for injection molding?

Which mat is best for cow?

Enhance Your Style: Vibrant O-Ring Color Dots

Boost Efficiency: Buy Quality Abrasion Rubber Dredger Hoses

What is HDPE pipe prices?

What are the properties of PTFE tubing?

What are the advantages of buying PP plates for the B2B purchase stage?

Furthermore, GAIM offers enhanced part quality and improved dimensional stability. The gas channels act as stress-relieving features within the component, minimizing the occurrence of warping, shrinkage, or sink marks. This results in parts with superior surface finishes and precise dimensions, meeting even the most stringent requirements.

The utilization of GAIM in custom injection molding also brings about economic advantages. The gas-assisted technique significantly reduces cycle times, allowing for faster production rates. The reduced cooling time, achieved by the gas channels dissipating heat effectively, enables shorter total production cycles. This increased productivity translates into lower costs per part and improved overall efficiency.

In conclusion, the gas-assisted injection molding technique reigns supreme in the realm of custom injection molding. Its ability to create hollow and lightweight parts with complex geometries, while reducing material consumption and improving part quality, sets it apart from other techniques. The economic advantages, such as faster production rates and lower costs per part, further solidify its position as the superior choice. As industries continue to demand innovative and efficient manufacturing solutions, GAIM proves itself as the go-to technique for achieving superior plastic components.

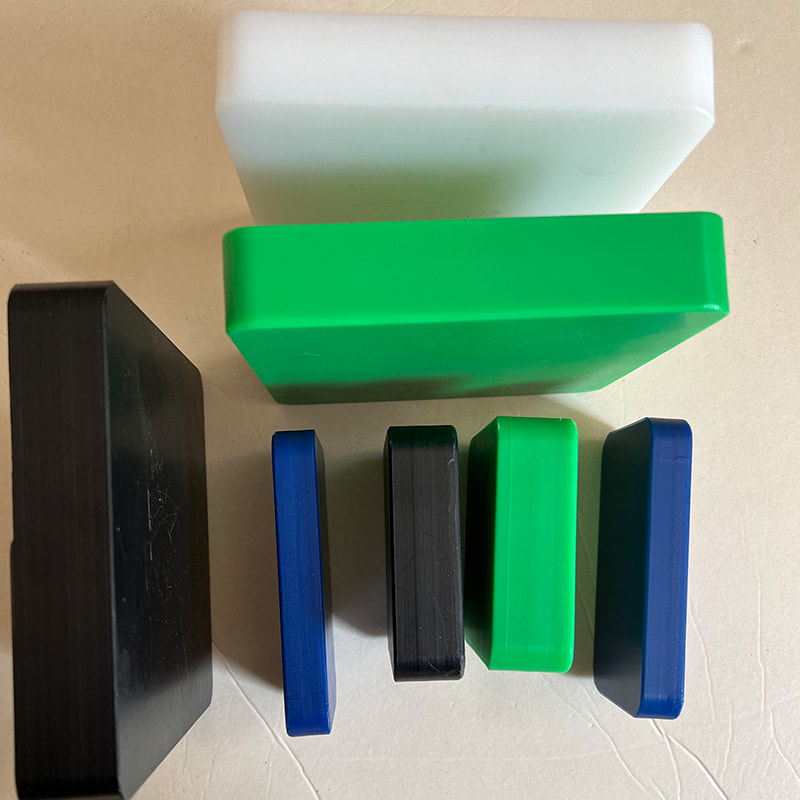

Contact us to discuss your requirements of Uhmw Plastic Sheet, Wholesale Pp Sheet, Plastic Cnc Machining. Our experienced sales team can help you identify the options that best suit your needs.

Additional resources:What is FKM used for?

What is HDPE pipe prices?

What are the advantages of uPVC pipe?

Which supplier offers the best nylon sheets for sale?

Which Innovative Projects Can Utilize 6mm Plastic Sheets?

How do you keep rubber mats from slipping?

Vintage T-Shape Bakelite Knobs: Timeless Elegance

76

0

0

Related Articles

-

Which HDPE pipe prices in Kenya offer the best value for money?

Which HDPE pipe prices in Kenya offer the best value for money?

62

0

0

-

65

0

0

-

45

0

0

-

47

0

0

-

Which factors to consider when purchasing UHMW-PE fender panels and sills?

Which factors to consider when purchasing UHMW-PE fender panels and sills?

60

0

0

-

57

0

0

-

54

0

0

-

59

0

0

Comments

All Comments (0)